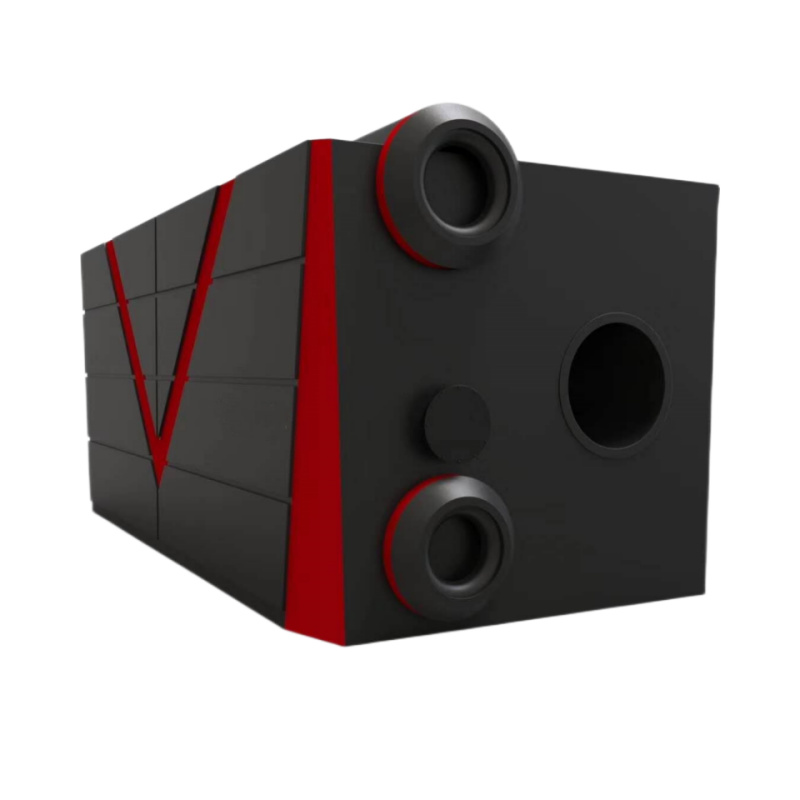

工业燃气蒸汽锅炉

10t/h 15t/h 25t/h 30t/h天然气蒸汽锅炉出售

产品畅销,性价比高

特征

Ø 自动控制运行/安全可靠/使用寿命长

Ø 最大火力可达110t/h(约105,050HP)

Ø 食品饮料、纺织/化工/石油/包装行业应用,ETC。

Ø 额定蒸汽量:20t/h-110t/h(约19,100HP-105,050HP)

Ø 饱和蒸气:104-225℃ 过热蒸汽温度:250℃、300元、350元、400元、450元

Ø 核心控制方式:PLC+PC控制、DCS控制

Ø 热效率(%):~98%

介绍

系统

评论

工业燃气蒸汽锅炉介绍

System of the Industrial Gas Fired Steam Boiler

Composition of Boiler System

·Combustion system

·Steam water system

·Control system

• Combustion system of the gas fired steam boiler

The combustion system supplies fuel to the boiler for heat generation.

Gas/Oil fired steam boilers' combustion system equips with burner and fuel device according to the fuel properties,steam capacity and pressure of the boiler.

Burner brands: Baltur, Riello, Weishaupt, Hofamat, Honeywell, Ecoflam, Cavallo and so on.

• Steam water system of the industrial gas fired steam boiler

The steam water system consists of a feedwater part and a steam part.

Feedwater part: Feedwater refers to the water that is provided to the boiler for steam conversion. The feedwater channels water into the boiler and automatically controls it to satisfy steam requirements.

Steam part: the steam is the part of the boiler responsible for collecting and regulating the steam generated by the boiler. Valves and pressure gauge controls are used to monitor and regulate steam pressure.

The steam and water system should be composed of the boiler's main body, rear heating surface(such as economizer, condenser and so on which are equipped according to the actual situation of the user), water treatment device, feedwater pump, steam header, deaerator and so on.

• Control system of the industrial gas fired steam boiler

The boiler control system is a collection of boiler electrical control components, a center for collecting and processing boiler operating signals, and an operation platform for sending execution instructions to each execution unit of the boiler.

If you want the boiler system to realize the IoT(Internet of Things) service for boiler system, we can provide you with this service when designing the control system.

The IoT system for boiler system adopts a layered structure design, namely data collection layer(M BOX), cloud platform(M SERVICE), and application layer(MYZT application system).

The control system of the industrial gas fired steam boiler provides the control of boiler water level,pressure, burning,safety protection and so on.

Control principle: Through the real-time data collection,monitoring and processing of boiler water level, pressure, flue temperature and burner, the purpose of intelligent and safe operation is achieved.

★ The Core Control Mode of the steam boiler system: PC control, PLC+PC control, DCS control. The screens of the natural gas steam boiler high efficiency is as follow:

★ Standard Control Content:boiler water level,steam pressure control,alarm and interlock,and set up an automatic control system for combustion start and stop.

★ Steam Boiler Control Modes of Operation: Automatic and Manual

a) The boiler in automatic mode is in fully automatic operation state,

b) Manual mode: The operation of the boiler equipment is controlled by manual operation. Under normal circumstances, the boiler should operate in the automatic operation state. In special cases,it will be required to switch to the manual state.

★ Control system detection data sources: burners, temperature sensors, pressure transmitters, pressure controllers, liquid level gauges, flow meters, electric regulating valves, and other remote instrument valves.

Company profile

CN BOILER ENGINEERING SOLUTION LLC is a comprehensive service provider of thermal energy systems in China, devotes to providing for customer one-step thermal energy system solutions by safety, save energy, environmental,intelligent and reliable. Main products include industrial boilers(hot water boilers, steam boilers, thermal oil boilers, waste heat boilers and CFB boilers), steam generator(electric steam generator, electric hot water generator), intelligent control system by PLC control, PLC+PC control or DCS control, remote instrument and valves and so on.The control system includes industrial boiler control system(oil fired boilers, gas fired boilers, biomass fired boilers, coal fired boilers, electric boilers, waster heat boilers, CFB boilers), PLC deaerator control system, condensate recovery system, reactor control system, heating exchanger control system, hot air boiler control system etc.

分享你的意见

显示中

6

的

0

评论

最近的

热门评论

阅读更多

你的评分

你的意见 *

姓名 *

输入你的名字

电子邮件 *

输入你的电子邮箱

提交

立即联系我们

输入您的询问详情,我们将在 24 小时内回复您。

Name can't be empty

邮箱不能为空

Company can't be empty

Phone can't be empty

电话

Products can't be empty

您想要的产品

留言不能为空

验证码错误

撤回